Difference between revisions of "DIY - Vacuum Forming Box"

(→Parts & Pieces) |

(→Base Build) |

||

| Line 88: | Line 88: | ||

=== Base Build === | === Base Build === | ||

| + | |||

| + | I started with the wood box. Using the 10" Chop saw I could make the corners nearly perfectly square which is a big plus. | ||

| + | <br> | ||

{| border="0" cellspacing="1" cellpadding="1" width="800" align="center" | {| border="0" cellspacing="1" cellpadding="1" width="800" align="center" | ||

| Line 95: | Line 98: | ||

| align="center" | Cut wood pieces and box build | | align="center" | Cut wood pieces and box build | ||

|} | |} | ||

| + | <br> | ||

| + | |||

| + | I had a set of picture frame corner clamps which make the set-up and alignment of the corners super easy and solid. | ||

<br> | <br> | ||

| Line 103: | Line 109: | ||

| align="center" | Corner clamps | | align="center" | Corner clamps | ||

|} | |} | ||

| + | <br> | ||

| + | |||

| + | After the four corners were complete, I set everything else up and glued them all in with clamps to hold it all in place. | ||

<br> | <br> | ||

| Line 111: | Line 120: | ||

| align="center" | Box build | | align="center" | Box build | ||

|} | |} | ||

| + | <br> | ||

| + | |||

| + | With the box completed I then needed to put the two top pieces together and drill the vacuum deck. | ||

<br> | <br> | ||

| Line 119: | Line 131: | ||

| align="center" | Box and top parts | | align="center" | Box and top parts | ||

|} | |} | ||

| + | <br> | ||

| + | |||

| + | I laid out the hole pattern on my computer and printed a template that I used to center-mark the holes. | ||

<br> | <br> | ||

Revision as of 12:43, 6 June 2018

© Mark Qvale - June, 2018

| |

| New DIY Tool |

Introduction

After doing hundreds of 3D prints for canopies, skids, shields, et., I decided to build my own Vacuum Forming box so I could get the weight dramatically down on some these parts. I did a pile of research and found many different styles and sizes but finally decided to simply take the things I liked in many pictures found on google and design my own. This then is my version.

Tools I Used

Besides the basic hand tools, these power tools helped immensly with keeping things sized and squared perfectly.

- 1. 10" Chop saw w/60 tooth carbide blade

- 2. Drill press

- 3. 10" Table saw

Parts & Pieces

Here is the complete parts list for this project. All dimensions and screw specs for this project are imperial (inches). The dimensions for the wood cut pieces are based on perfectly sized wood so if you copy this you will need to make adjustments based on the wood you select.

Cut List

- Hardwood 3/4 x 2-3/4 x 11-1/2

- Hardwood 3/4 x 3-1/4 x 24

- Hardwood 3/4 x 3-1/4 x 11-1/5

- Hardwood 5/8 x 1-1/2 x 2

- Hardwood 3/4 x 2-3/4 x 10

- Hardwood 3/4 x 2-3/4 x 10-1/8

- Plywood 1/4 x 11-1/2 x 24

- Plywood 1/4 x 11-1/2 x 14

- Pine Laminate 1 x 8 x 10

- Alum Flatbar 1/8 x 1 x 3-1/2

- Alum Angle 1/16 x 1/2 x 1/2 x 14L

- Alum Angle 1/16 x 1/2 x 1/2 x 10-1/2L

- Alum Angle 1/16 x 1/2 x 1/2 x 9-1/2L

- Alum Angle 1/16 x 1/2 x 1/2 x 11-1/4L

- Wood Dowel 1/2D x 10-1/2L

- Heat Box 2-3/4 x 10-3/16 x 8-7/16

Hardware

- 4x #8 x 1-1/4" wood Screws

- 12x #4 x 3/4" wood screws

- 4x #8-32 x 2" round head machine screws

- 5x #8-32 x 1" pan head machine screws

- 20x #6-32 x 3/8" flat head machine screws

- 8x #6-32 x 3/8" pan head machine screws

- 2x #12-24 x 3/4" button head machine screws

- 9x #8-32 hex nuts

- 28x #6-32 hex nuts

- 2x #12 nylok hex nuts

- 14x #8 flat washers

- 2x 3/16 x 3/8 x 3/16 nylon spacers

- 8x small steel flat corner brackets

- 5x 3/16 x 1/2 x 3/8L phenolic spacers

- 4x 1/2 x 5/8D rubber feet w/screws

Heater Components

- Walmart Toaster Oven

The Build

First Things First

Toaster Oven

While reading many articles on how to create an effective heating element I found a YouTube video from a guy who was simply using a toaster oven to heat the plastic in an aluminum frame. So, I bought a toaster oven at Wallmart for $19 and gave this method a try. I found that these heating elements provided more than enough heat for this purpose so I incorporated the heat elements and the complete oven control system in my design.

|

| WallMart toaster oven |

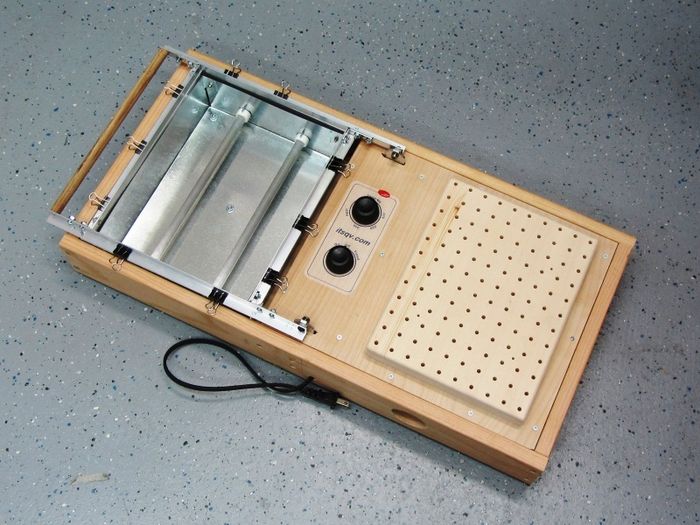

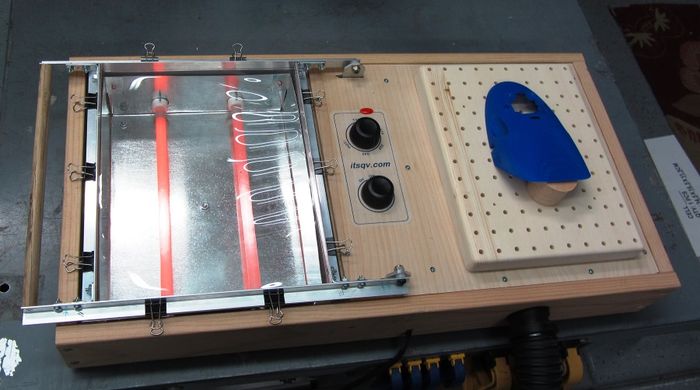

Base Build

I started with the wood box. Using the 10" Chop saw I could make the corners nearly perfectly square which is a big plus.

|

| Cut wood pieces and box build |

I had a set of picture frame corner clamps which make the set-up and alignment of the corners super easy and solid.

|

| Corner clamps |

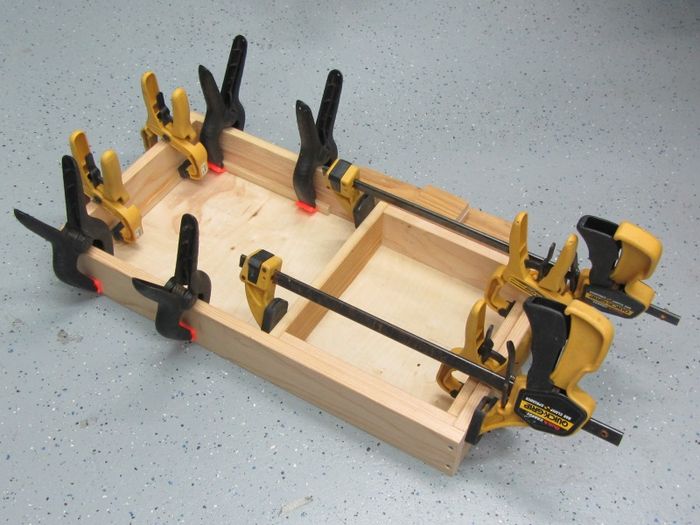

After the four corners were complete, I set everything else up and glued them all in with clamps to hold it all in place.

|

| Box build |

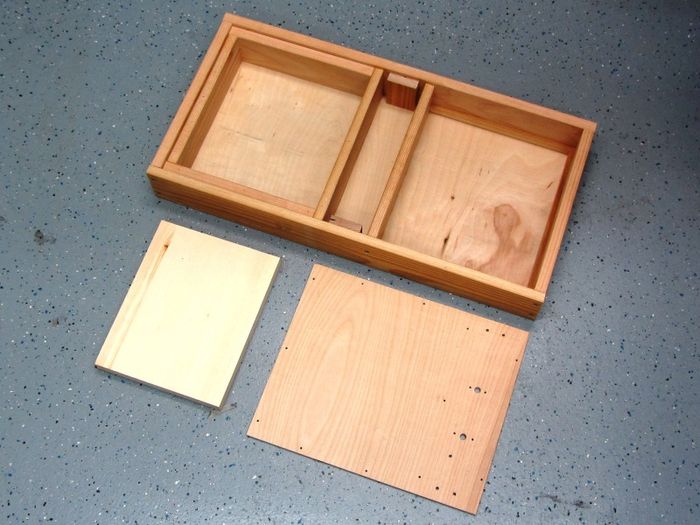

With the box completed I then needed to put the two top pieces together and drill the vacuum deck.

|

| Box and top parts |

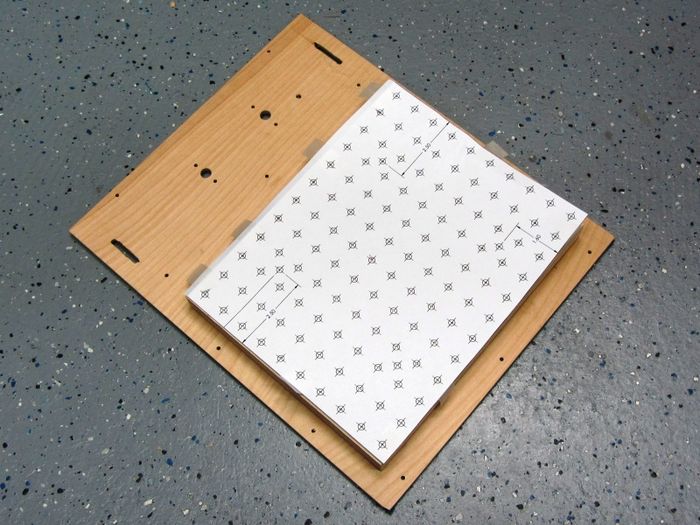

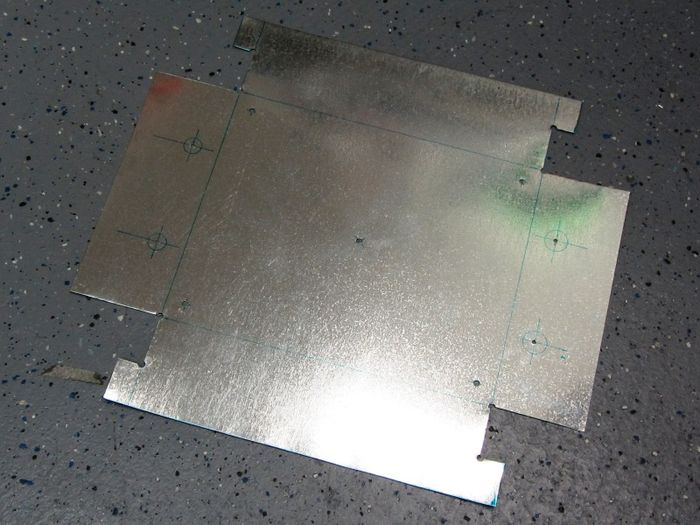

I laid out the hole pattern on my computer and printed a template that I used to center-mark the holes.

|

| Template for marking and drilling the vac holes |

Frame Build

|

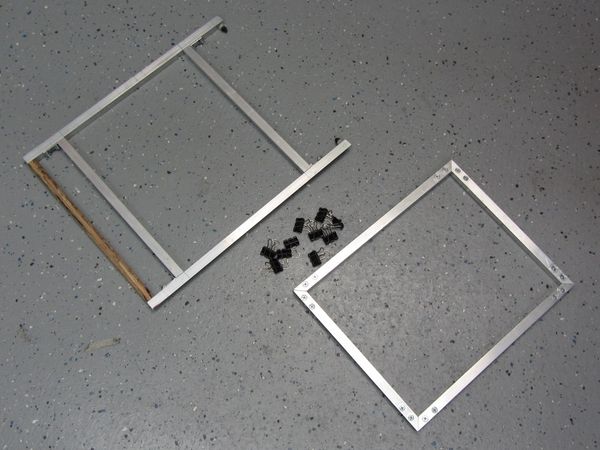

| Aluminum frame components |

|

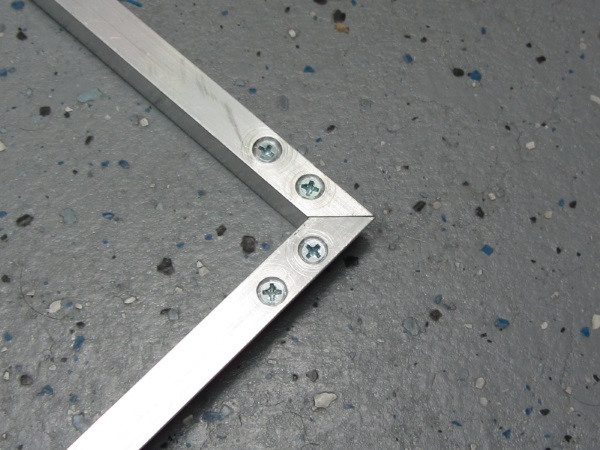

| Clamp frame corner detail |

|

| Main frame joint detail |

|

| Completed frames |

|

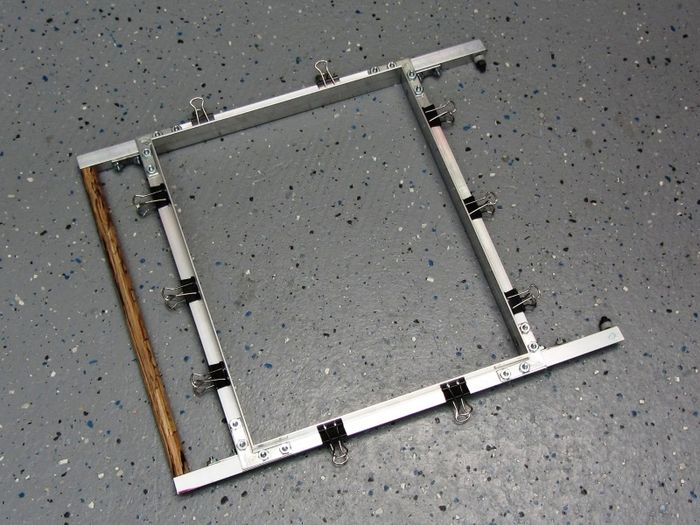

| Completed and mounted frames |

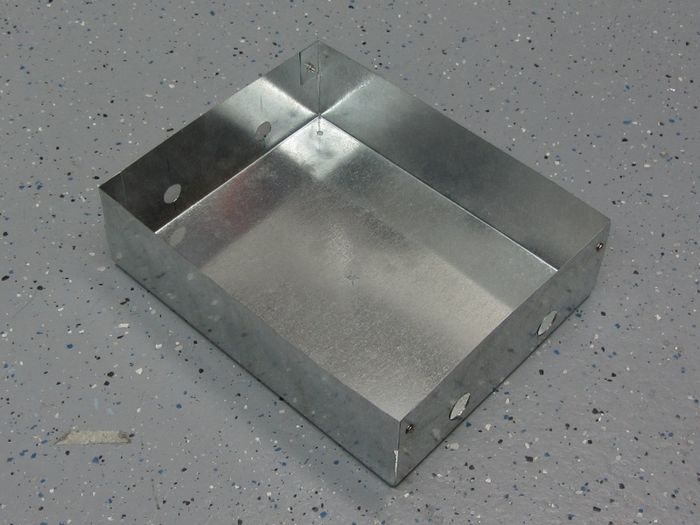

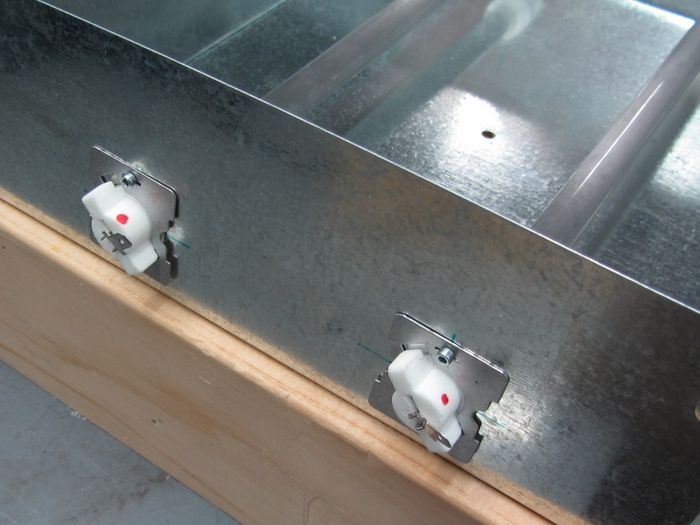

Heat Box Build

|

| Sheetmetal layout and cut |

|

| Completed heat box |

|

| Heat element mount detail |

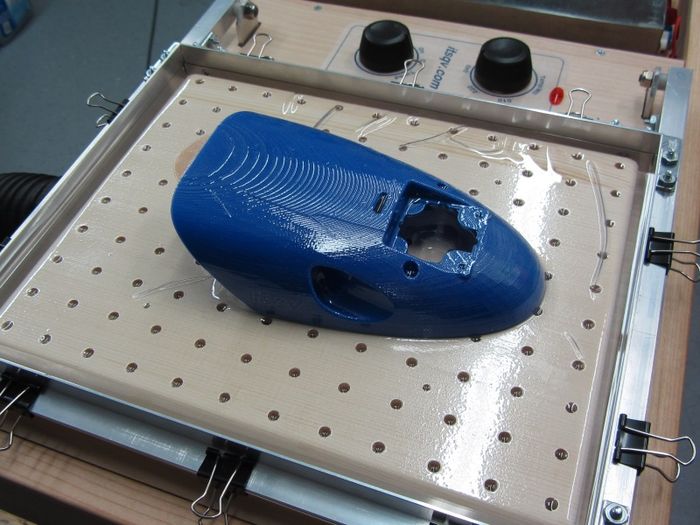

First Mold!

|

| Wait for it! |

|

| What's that sucking sound? |

|

| A very light, near perfect replacement part! |

See Also

TBA