Difference between revisions of "GWS S125-1T Servo Mod"

(Created page with " <i>September 2015</i><br> <br> {| cellspacing="1" cellpadding="1" width="95%" border="0" |- | align="left" valign="bottom" width="50%" | __TOC__ | align="right" width="50%"...") |

|||

| Line 5: | Line 5: | ||

|- | |- | ||

| align="left" valign="bottom" width="50%" | __TOC__ | | align="left" valign="bottom" width="50%" | __TOC__ | ||

| − | | align="right" width="50%" | [[File: | + | | align="right" width="50%" | [[File:GWS01.jpg|600px]] |

|- | |- | ||

| | | | ||

| Line 14: | Line 14: | ||

== Introduction == | == Introduction == | ||

| − | So, I wanted a digital version of the GWS 1 turn servo to help with RF glitching, centering and to give me the ability to possibly program the end and center points. | + | So, I wanted a digital version of the GWS S125-1 turn servo to help with RF glitching, centering and to give me the ability to possibly program the end and center points. |

| + | <br><br> | ||

| − | + | === The GWS Servo === | |

| + | |||

| + | The <u>current version</u> of the GWS S125-1T Sail Winch servo has decent centering characteristics, will actually travel 385 degrees, it's quite smooth and makes monster torque (~7kg). It is important to note that there are two versions of this servo, one with 23 tooth spline which was discontinued 2 years ago and the one for this project which has a 25 tooth spline identical to Futaba.<br><br> | ||

| + | |||

| + | The easiest way to tell the difference is to look at the servo sticker. | ||

| + | <br> | ||

| + | '''Made in China'''<br> | ||

| + | |||

| + | :* This servo has a 23 tooth (JR) spline | ||

| + | :* Servo centering will error up to 10 degrees | ||

| + | :* This servo was discontinued by GWS in late 2014 | ||

| + | <br><br> | ||

| + | |||

| + | '''Made in Taiwan'''<br> | ||

| + | |||

| + | :* This servo has a 25 tooth (Futaba) spline | ||

| + | :* Servo centering will error up to 5 degrees | ||

| + | :* This servo is the current model (as of Oct 2014) | ||

<br> | <br> | ||

| + | |||

| + | [[File:GWS_servos.jpg|800px]] | ||

| + | |||

| + | === The Mod === | ||

| + | |||

| + | After searching for a very long time for a replacement servo I finally came to the conclusion that the best I could do was to modify the existing servo. I started looking for digital servos that had a small enough board to fit inside the GWS case and it turns out there are many. After trying a few with decent results, I gave a Hitec HS-5245MG board a try and it worked beautifully. It easily fits in the case and it retains all the program functionality. | ||

| + | <br> | ||

| + | |||

| + | I found one of these on ebay that was a "parts" servo for $10 so it wasn't too expensive. I already had a Hitec program box from my 3D days so that helped keep it cheap. With the program box, the parameters you can change are-<br> | ||

| + | |||

| + | : Servo Speed | ||

| + | : Deadband | ||

| + | : Endpoints | ||

| + | : Center | ||

| + | |||

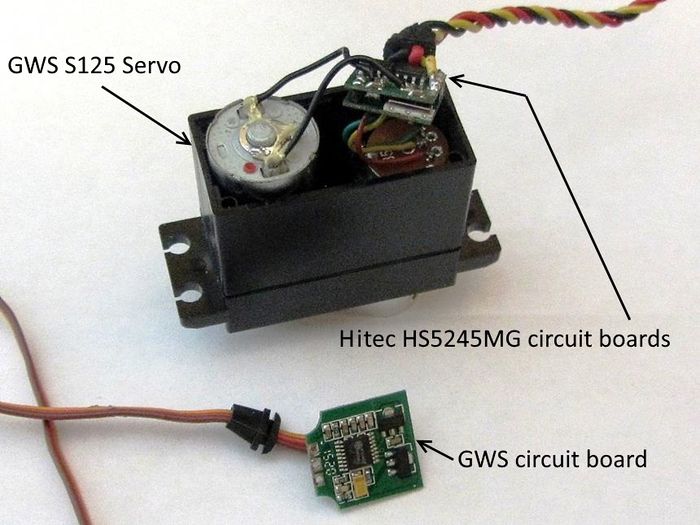

| + | [[File:GWS_Boards.jpg|700px]] | ||

| + | |||

| + | Even without the program box the servo works better! No more RF glitches, centering is better than 5 degrees and it runs smoother. | ||

Revision as of 21:43, 15 June 2018

September 2015

Contents |

|

| Modded! |

Introduction

So, I wanted a digital version of the GWS S125-1 turn servo to help with RF glitching, centering and to give me the ability to possibly program the end and center points.

The GWS Servo

The current version of the GWS S125-1T Sail Winch servo has decent centering characteristics, will actually travel 385 degrees, it's quite smooth and makes monster torque (~7kg). It is important to note that there are two versions of this servo, one with 23 tooth spline which was discontinued 2 years ago and the one for this project which has a 25 tooth spline identical to Futaba.

The easiest way to tell the difference is to look at the servo sticker.

Made in China

- This servo has a 23 tooth (JR) spline

- Servo centering will error up to 10 degrees

- This servo was discontinued by GWS in late 2014

Made in Taiwan

- This servo has a 25 tooth (Futaba) spline

- Servo centering will error up to 5 degrees

- This servo is the current model (as of Oct 2014)

The Mod

After searching for a very long time for a replacement servo I finally came to the conclusion that the best I could do was to modify the existing servo. I started looking for digital servos that had a small enough board to fit inside the GWS case and it turns out there are many. After trying a few with decent results, I gave a Hitec HS-5245MG board a try and it worked beautifully. It easily fits in the case and it retains all the program functionality.

I found one of these on ebay that was a "parts" servo for $10 so it wasn't too expensive. I already had a Hitec program box from my 3D days so that helped keep it cheap. With the program box, the parameters you can change are-

- Servo Speed

- Deadband

- Endpoints

- Center

Even without the program box the servo works better! No more RF glitches, centering is better than 5 degrees and it runs smoother.