Dynamic Motor and Prop Balancer

Redirect page

Redirect to:

© Mark Qvale - November, 2017

| |

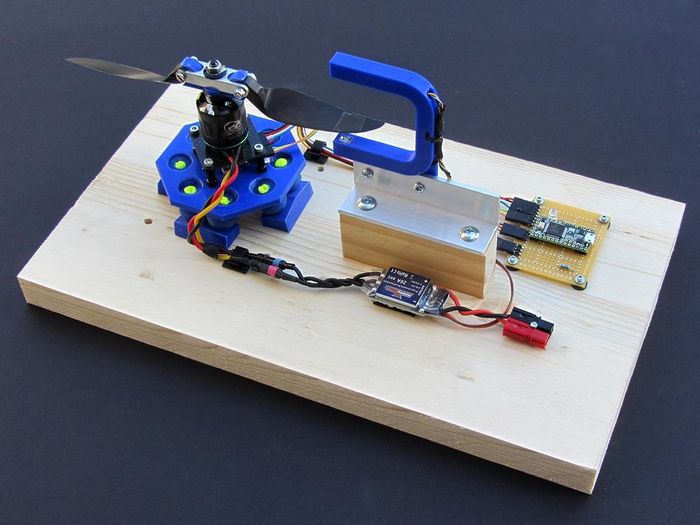

| Balancer shown with an Aeronaut 8x7 folding prop |

Introduction

This project was actually done some years ago by some great posters on RCGroups and DoItYourselfDrones. Please see the Acknowledgements section at the bottom of this page. You can (& must!) read the original threads at these two links:

Basically, this is a fairly high precision dynamic balancer for motors and props that can be built for $60 or less. If built well, it does a fantastic job on both motors and props saving huge amounts time over manual balancing and doing a much better job. If you want to create jello free video this type of tool is what you need.

My Build

This has been a very fun project for me having spent a large part of my life as a machinery designer.

My build here is but one of many versions you can find on RCGroups. I designed the cushion arrangement to more effectivly distribute the un-balanced load for a cleaner measure. I don't know if it actually works better than the four point cushion mounts others have built but it does work well.

The purchased components I have selected are the more expensive of the many different components mentioned but I felt they had the best guarantee of success. The 3D parts are all of my own design and have proven out well. I used ABS as a print material although PLA or PETG would also work just fine.

Parts

The purchased parts listed here are what I chose for this project. There are veriations of most of these you can see on the RCGroups thread. If you do choose different components, keep in mind your particular wiring may change and this information too can be found on the thread. The first five parts include links to where I bought them.

Purchase Parts

- Teensy USB Microcontroller, Version 3.2

- 3-Axis ADXL345 Digital Acceleration Module

- QEE123 - Plastic Infrared Light Emitting Diode

- QSE159 - Silicon Photosensor

- 300g Gimbal cushions

- Datak 1.93" x 2.33" Protoboard #12-606

- 56 ohm 1/4 watt resistor

- 100 ohm 1/4 watt resistor

- 10K ohm 1/4 watt resistor

- Standard Red LED

- Pin Headers

- M3 x 15mm Aluminum Stand-offs

Make Parts

The "make" parts listed below include three 3D printed parts, a simple flate piece motor mount, the control board and a wood base. You are certainly free to change any of this and there are many versions of all of these pieces found on the thread. The STL print files can be found near the bottom of this page under "3D Print Parts".

- Photo Sensor mount

- Cushion Bases

- Balance platform

- Motor mount plate

- Teensy control board

- Wood base

IR Photo-sensor Mount

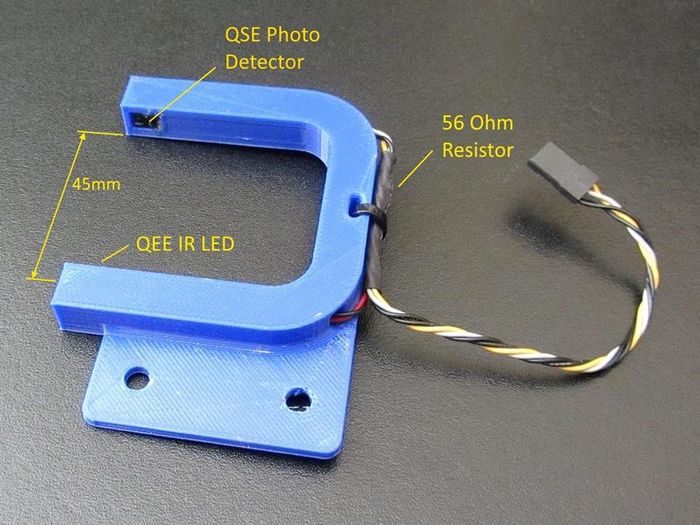

The photo sensor mount has a gap of 45mm for the blade to pass through which for the motor and prop sizes I have built it for works well. I mounted the IR detector on the top and the IR LED on the bottom so it wouldn't be susceptible to IR from ambient room light.

|

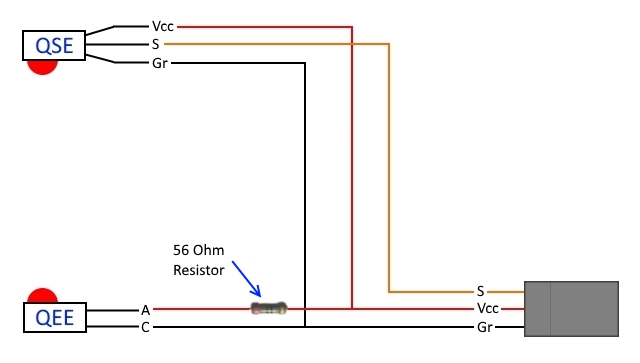

The wiring for this includes the 56 Ohm resistor in the wiring on the mount itself.

NOTE: The original wiring picture showed an incorrect wiring to the QEE LED. This has now been corrected.

|

Mount Mod

When doing balancing I noticed a fair bit of noise and also noticed the sensor mount was resonating/vibrating a bit. To reduce any effect this might have, I changed the mount to use a pair of rubber grommets and this has eliminated the vibration that I can see or feel.

|

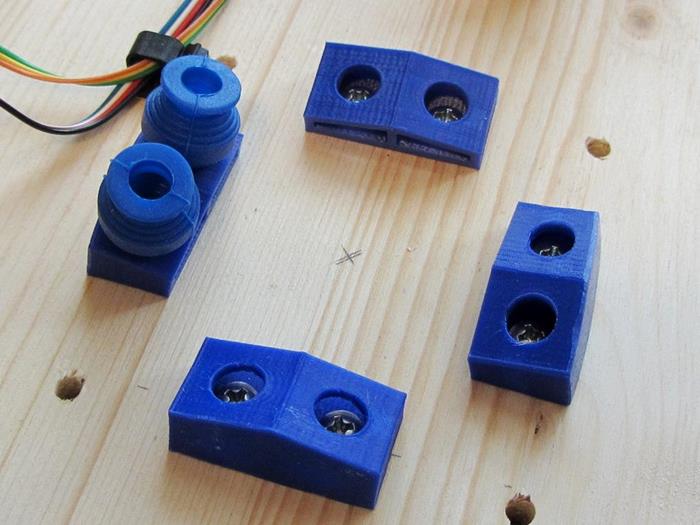

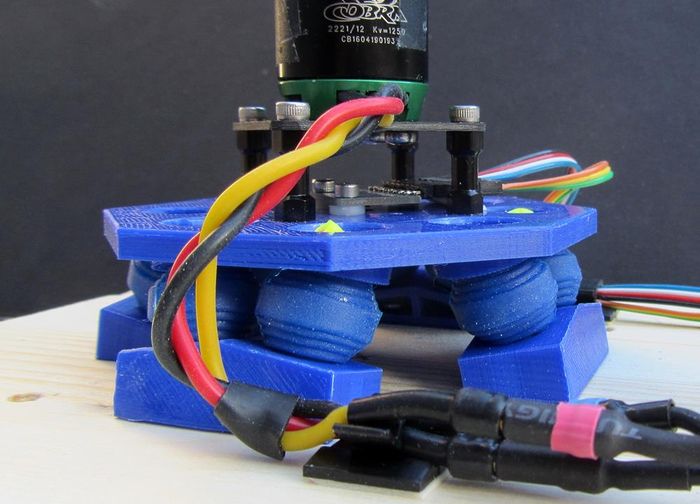

Cushion Base

Cushion selection is somewhat dependent on the size of motors and props you plan to balance. Many posters have opted for the bobbin style cushions that have a stud out each end and they are putting them on 4 evenly spaced corners. I decided I wanted more cushions in a more circular pattern to help more clearly define the direction of the imbalance. With that idea I chose to try normal 100g gimbal cushions which are working very well. In the pictures you can see I have them stuffed with yellow foam earplugs as a means to dampen high frequency noise which does work. I have also ordered another set of the 300g cushions (listed above) because I think it could be a little stiffer

The Cushion Base is made up of four printed parts. Each base part has the cushion leaning inward at an angle of 12 degrees and left/right by 10 degrees. This helps to limit the effect of torque on this type of cushion arrangement and brings the tilt action more in line with the platform rotation.

|

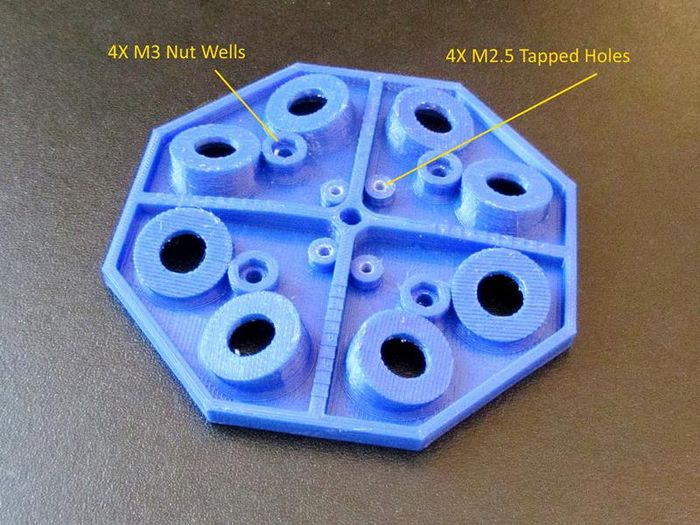

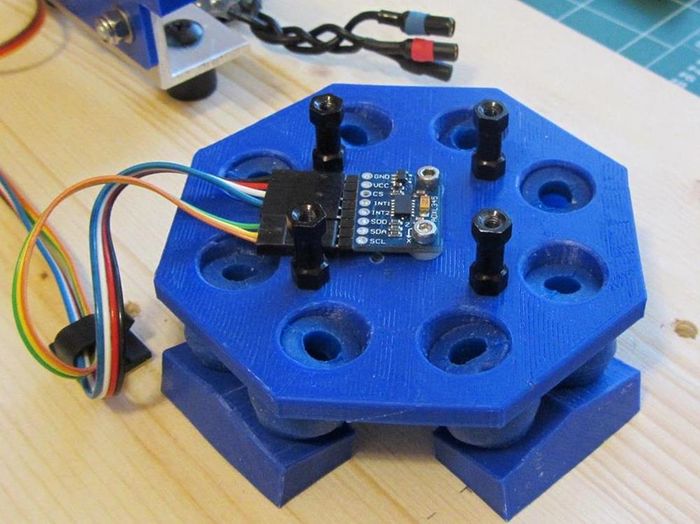

Balance Platform

The balance platform is printed in ABS with support upside down. It has four "nut wells" for four M3 plain nuts and four holes tapped to M2.5 to hold either the Adafruit ADXL345 accelerometer or the ones found on Ebay (require slightly different wiring). The aluminum standoffs shown are M3 x 15mm but any size will do that clears the ADXL unit. You should put foam or servo tape under the ADXL to dampen high frequency vibration

|

|

|

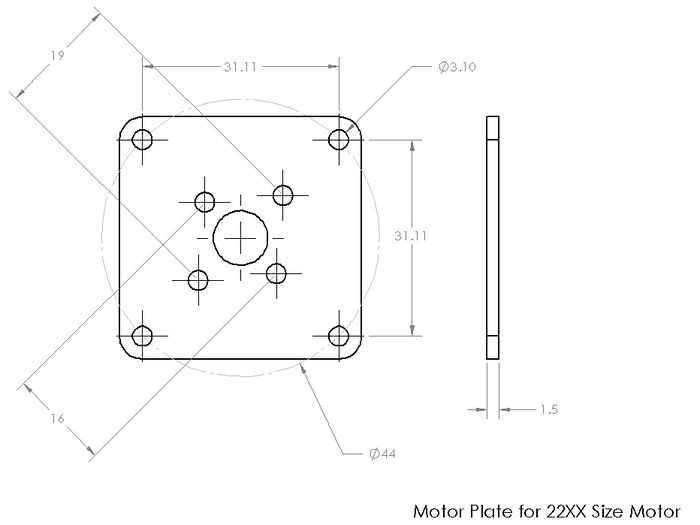

Motor Plate

I made the motor plate out of a piece of 1.5mm Carbon Fiber. The bolt holes that attach to the stand-offs are on a 44mm circle which is the same as many 28xx size cross mounts. You could also use G10 fiberglass or even plywood for this providing it doesn't flex. I did not make this a printed part because there are so many different motor mount screw sizes and configurations.

|

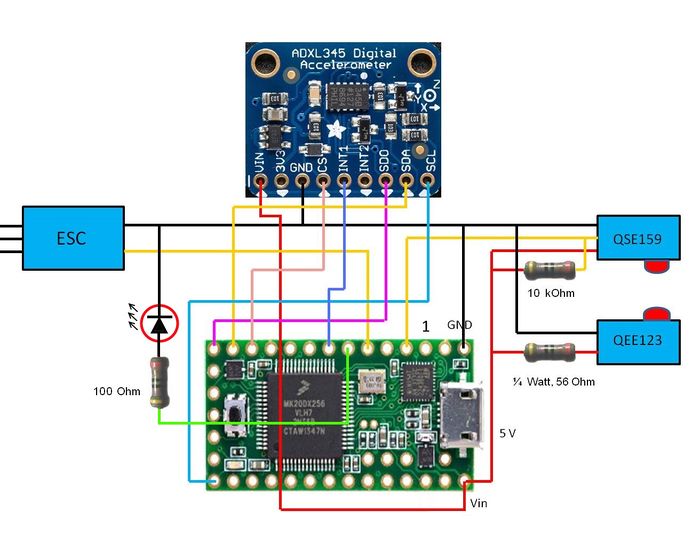

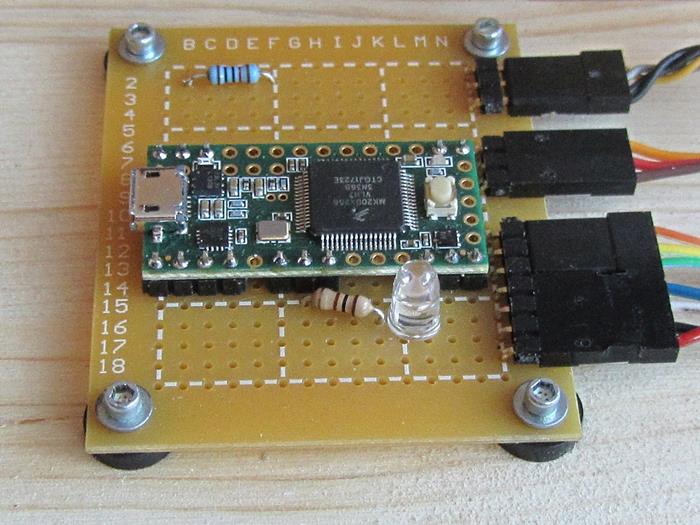

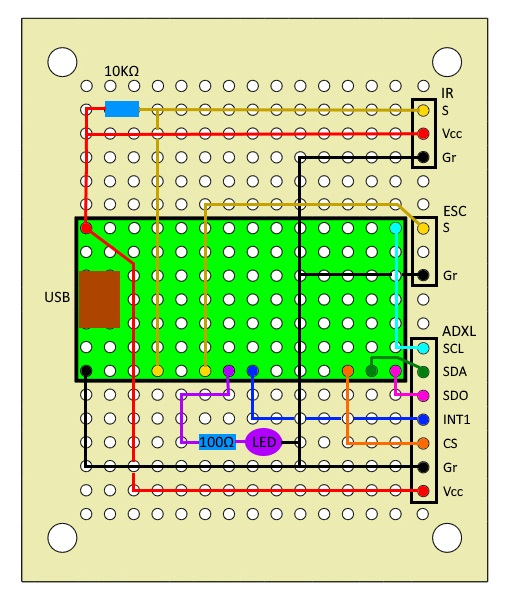

Control Board

In the original write-ups there are two micro-controller/control boards with separate firmwares but my build only covers wiring and components useing the Teensy 3.2 micro-controller. The wiring shown here and the wiring shown for the IR Photo sensor is derived from several drawings on the RCGroups thread. Some differences are I added an LED indicator so you get a visual of when the prop crosses the beam. I also have the ADXL Vin pin wired directly into the Vin terminal of the Teensy board (5v) which is different from other drawings you may find but this has worked perfectly for me.

|

| My complete wiring diagram with Adafruit ADXL345 |

|

| My completed control board |

|

| My control board wiring (top view) |

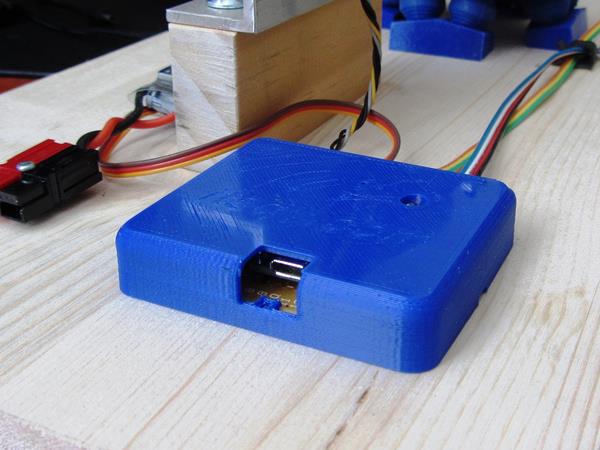

Cover It!

I decided I didn't like the exposed control board so I made a cover that snaps in place. This one will only fit the board I purchased so you will have to modify it for the board you purchased.

|

Firmware, Software & Initial Setup

The firmware and Software can be found through the links below. The firmware will just load up on the Teensy board but the software needs a free license key which you can get from the creator (first poster), cyborgcnc. Simply click on the mail icon below his name on RCGroups and request the key.

For more information on the firmware, software and how to get this all working please carefully read through the RCGroups thread.

- DPBalance Software

- http://www.cncguitar.com/Balancer/DPBalance1.3.rar

Software Images

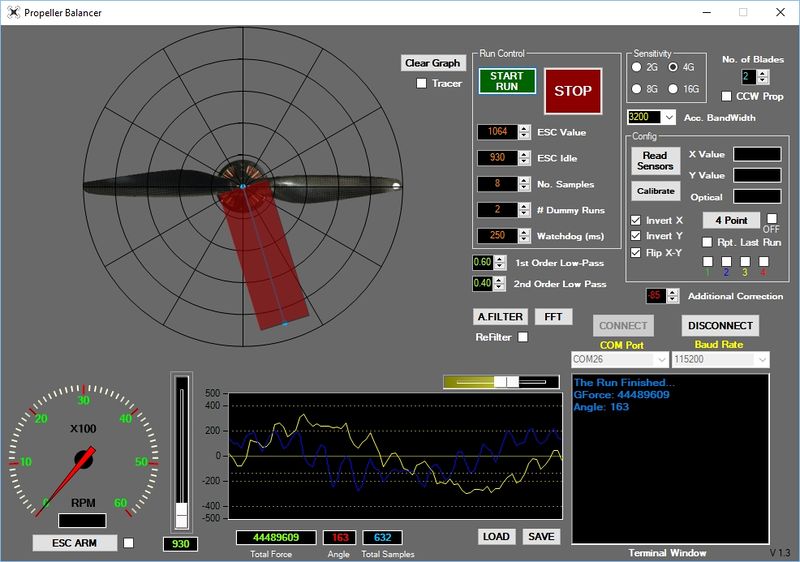

|

| The software user interface |

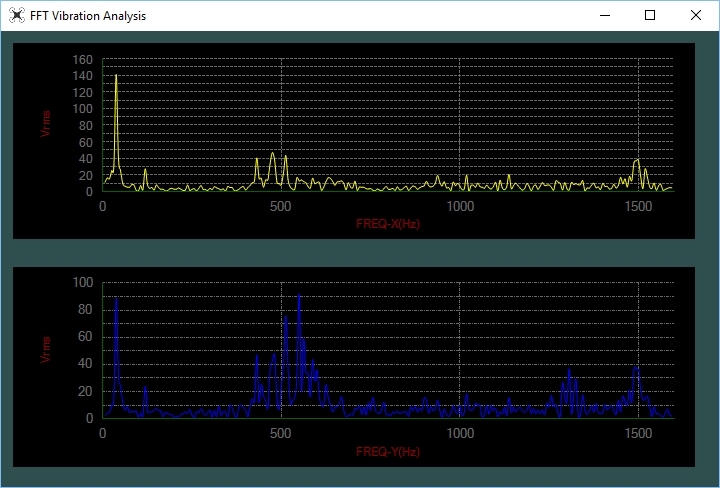

|

| Vibration analysis chart - unbalanced and unfiltered |

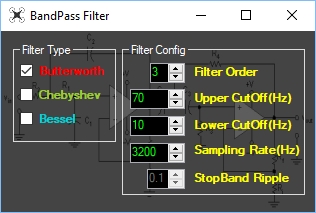

|

| Bandpass filter settings |

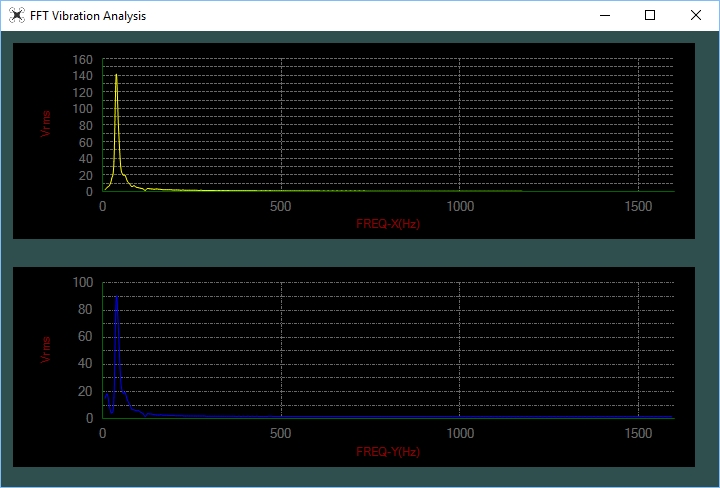

|

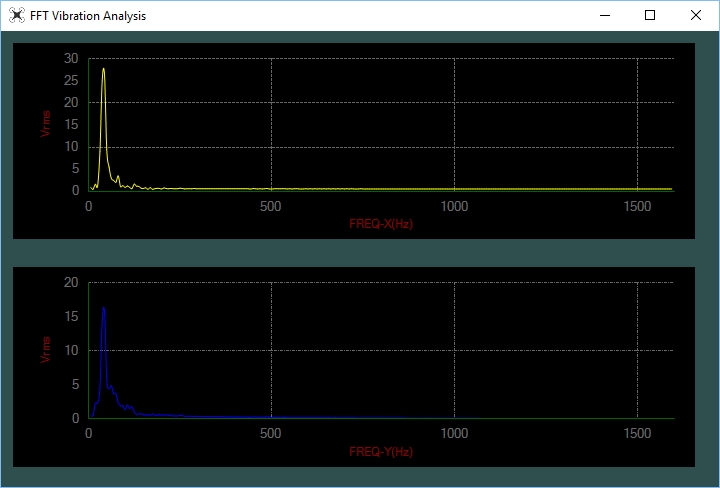

| Vibration analysis chart - unbalanced and filtered |

|

| Vibration analysis chart - balanced and filtered (5x improvement!) |

Issues Found

- 1. First and foremost - LIGHT!

- I was testing on my desk and the IR trigger wasn't working, at least until I shut the blinds on my window. DOH!

- 2. Sensor saturation

- If the cushions are too soft or if something is loose or rattling, the ADXL sensor can become over-saturated and give crazy results

3D Print Files

The following link will get you a zip folder which contains the print files and a drawing of my current motor plate:

Videos

The following excellent videos are provided by cyborgcnc:

Acknowledgements

Enormous thanks to the following folks who clearly spent a lot of time working to get this all working superbly!:

- Frank Al (diydrones 10/2012)

- The original creator of the DPB, initial softwares and first projects around this awesome, incredibly useful tool.

- cyborgcnc (RCGroups 01/2015)

- This poster has graciously supplied all the information I needed, firmware for the control board and extremely well done user interface for this project.

- adolfotregosa (RCGroups 03/2015)

- Provided great insight and help with development of the final software.

- lasakro (RCGroups 09/2015)

- Also provided lots of good insights and pictures of his work.

There are many more who contributed and are still developing but these four had the most influence on my particular build.

See Also

Comments? Questions?